42 how to use lock washers diagram

Lock washers typically replicate the fasteners head, and offers little improvement over not using one. A hardened flat washer has a larger seating area against the retained component. Although elongation of a retainer reduces applied tensions, disruption of the seat has a similar effect. The combination for your lock is either: - Placed on the back of your lock OR - Handed out to you by your school The combination is made up of three numbers - When entering your combination, you must enter the numbers in the order shown on the combination tag. The combination for this lock is: 38-16-22

McMaster-Carr is the complete source for your plant with over 700,000 products. 98% of products ordered ship from stock and deliver same or next day.

How to use lock washers diagram

Lock Washers: Lock washers are designed to secure fasteners that have a tendency to rotate or lose friction. Although though there are several different types of lock washers and is each designed for use with a particular fastener or application, they all work under the same principle. The washer is designed to exert a load, partially deform, and lock a fastener in place. (30A) Headlamp washers. F4 (15A)Sea theater. F5 (30A) Seat adjustment. F6 (20A) Heated rear window. F7 (5A) Door lock heater, central locking, alarm system, convertible roof. F8 (15A) Horn. F9 (20A) Audio system . F10 (30A)ABS/traction control, suspension adjustment. F11 (7,5A) Headlamp -left. F12 (7,5A) Headlamp -right. F13 (5A) Electric windows- rear (2door) F14 (30A) Electric windows. F15 ... Some of the lid lock mechanisms on washers are activated by heat, meaning bypassing them can be as easy as letting them cool down. Allow your Whirlpool washing machine to sit unplugged for at least 10 minutes. Then, attempt to lift the lid. If it will raise, then you’re all set! If the lid lock is still engaged, proceed with the steps outlined below. Step One: Turn off the Water. With your ...

How to use lock washers diagram. When you get the world of washers, you cannot deny the convenience they give you when you need to repair your household tools.However, many people, including myself, become confused when attempting to use bolt, nuts, and lock washers - since the differences between the two washers is hard to tell. Came here because I wanted to know more about the use of split ring lock washers. I had seen elsewhere that this type of lock washer was ineffective. What a surprise! Have been using them all my life. The order of jam nut and standard nut was a surprise too. Have been using them in the opposite sequence as long as I can remember. The flat washer can be used on the bolt side, nut side or both. If the assembly calls for o ther types of washers or hardware elements besides these two, they should go on before the lock washer. This way the tension created by the lock washer holds them all in place. It is very important that you do not tighten the lock washer too much. The lock washer prevents nuts and bolts from turning, slipping and coming loose because of vibration and torque. Different lock washers perform this function in ...

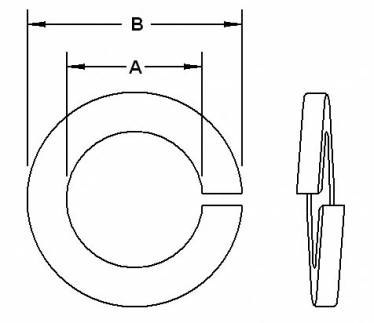

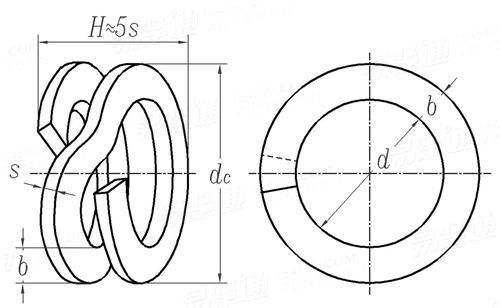

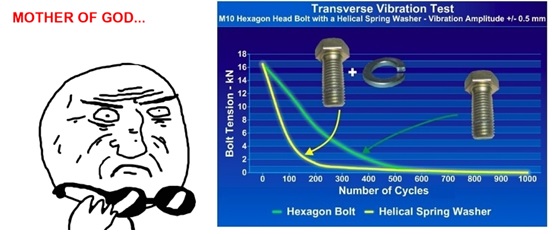

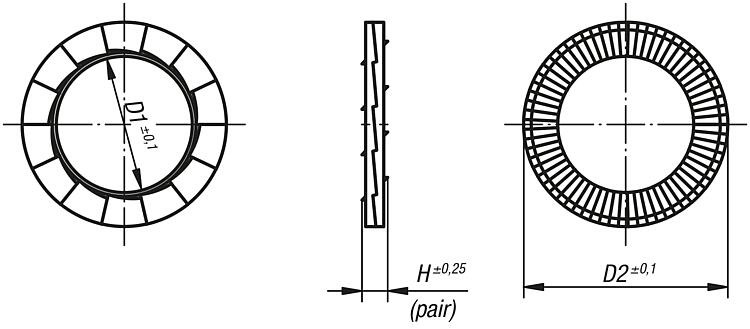

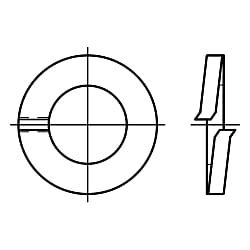

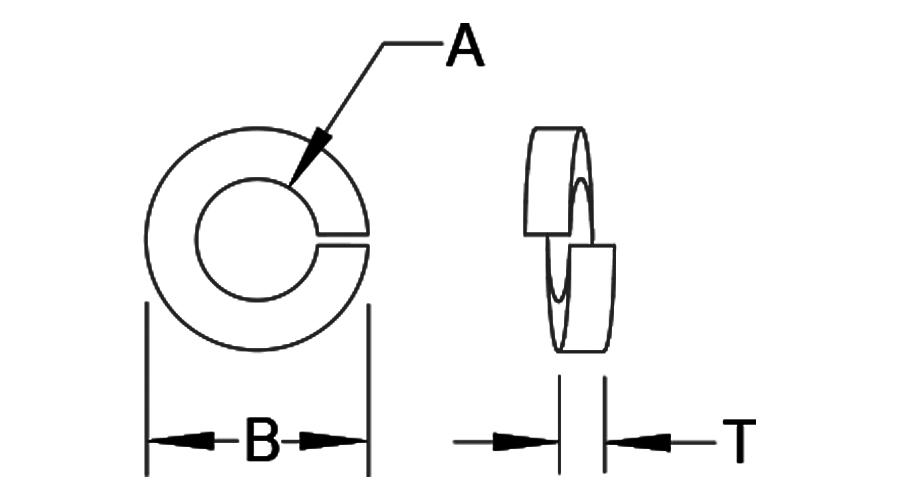

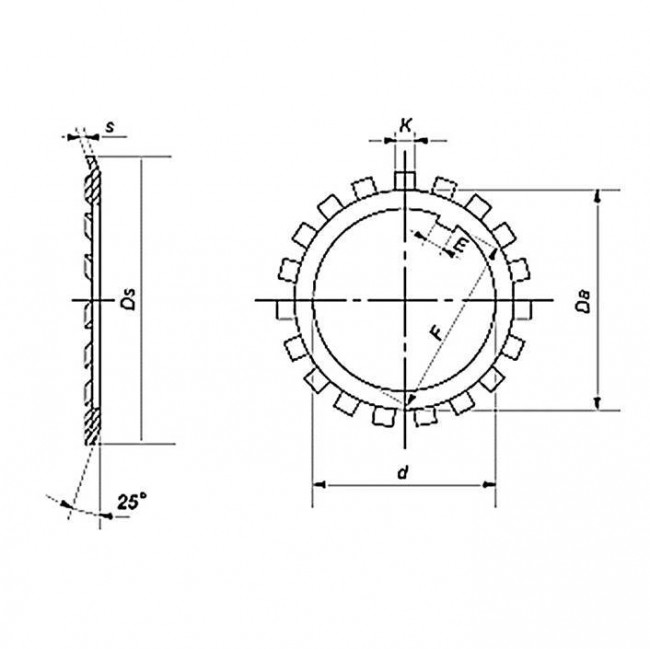

Helical spring lock washers are the most common form of lock washer and are best suited to applications with smaller loads. High-collar lock washers are a kind of split washer. Internal use lock washers have teeth made to bite into the nut/screw head and surface it contacts. They work best on small screws or screws used in electrical grounding. Particularly suitable for dynamic loads - including when using lubricants; Can be re-used; Very easy to install and remove (wedge lock washers are supplied as a pre-assembled pair) Also suitable for high-tensile bolts of 8.8, 10.9 and 12.9 and their respective nuts 2. Lock Washer. This form of lock washer is used to lock the nuts and bolts. These are many forms. Generally, six or more leaves are extended beyond the main diameter of the lock washer. After fixing this washer its leaves are bent on the sides of the nut or bolt. Thus, this washer prevents the nut bolts from getting loose. Spring Washer Installation. Spring washers are installed in an assembly the same way a regular flat washer is used; the washer is added under the nut during component assembly, and the nut is tightened to a specified torque. This pre-loads the spring washer to its correct load rating. Advertisement.

The lock washer grips into the surface below the screw or bolt head helping to prevent the threads from loosening over time. How to use lock washers diagram. This joint looks complicated but its only two cuts. Lock washers are usually used when bolting two pieces of metal together. 3x3custom tamar recommended for you. What would you call it. 3 Jul 2019 — The top ten list starts off with something controversial: split ring lock washers don't work. The original post cites a paper that claims ... Washers can follow ANSI, SAE, USS, and JIS sizes as well. We currently have a list of split lock, sealing, internal tooth, external tooth, flat, and flat retaining. Below I will go over what each one is and their use. Split Lock- Split locks are also called helical spring lock washers. These are made out of a spring coil that cut or split. Fuse box diagram (fuse layout), location and assignment of fuses and relays Ford Explorer Sport Trac (2000, 2001, 2002, 2003, 2004, 2005).

06.09.2020 · The other diagram shows 2x Victron Energy Orion DC-DC chargers – each rated for 30 amps for a matching total of 60 amps. The other difference in that the Renogy version shows a “pre-inverter load center” which might be useful in certain situations. However, if you have AC loads that should ONLY be powered by shore power, when shore power is connected (not inverted AC power), …

It depends on the need. If you are locking a nut to the base metal it is locking to -. use s star / split / double star / spring etc then the nut or a washer. and a nut. The washer spreads the presser across the nut and allows. it to rotate freely. If you are trying to lock the nut and the thread then.

12 steps1.Place the lock washer under the threaded fastener. When used correctly, a lock washer will hold the nut or other threaded fastener in place. To help it ...2.Make sure your washer is tight against the fastener and other surface. To operate correctly, your lock washer must press against both the threaded fastener ...3.Tighten your threaded fastener. For small, general purpose jobs, tighten your nut or threaded fastener by turning a wrench or ratchet clockwise. Do this ...

PLEATED SHADE REPAIR GUIDES Pleated shades are also called fabric, EvenPleat, and FashionPleat shades. They are fairly easy to repair. The most common repairs are replacing broken string, installing new mounting brackets, and replacing worn cord lock mechanisms. How-To & DIY Tips Show all Installation and Mounting

Buy 10 Sets 5 16 18 X 3 4 Stainless Steel Hex Head Screws Bolts Nuts Flat Lock Washers Kits 304 Stainless Steel 18 8 Fully Machine Thread Bright Finish Flat Washers Diameter 0 7 Online In Indonesia B0858rm8f5

How To Use Belleville Washers Correctly. To keep bolted connections tight, we can choose from several methods. The most common is the insertion of a locking device between the rotating part (nut) and the parts being fastened (i.e., bus bars). That locking device often is a split-ring lockwasher. Such a device does not meet all locking device ...

However general installation guidelines for lock washers will help you to choose what type of lock washer to use on your next project. Advertisement Step 1 Place an external tooth lock washer over the threads of a bolt or screw larger than 1/2-inch diameter. The head of the fastener should cover the teeth on the external lock washer.

Fuse box diagram (location and assignment of electrical fuses) for Volvo S40 (2004, 2005, 2006, 2007, 2008, 2009, 2010, 2011, 2012).

Lock washer. Flat washer. Nut. The lock washer is used to basically press into the material to grip onto it. The flat washer is used to create an even distribution of pressure from the nut. Both also create a larger holding surface for the nut and bolt to connect everything.

The outer diameter of regular Nord-Lock washers is designed for counterbore holes according to DIN 974, i.e. the washers fit under the head of standard bolts. Through-holes As for all locking washers, through-holes require two pairs of Nord-Lock washers - one pair for securing the bolt and a second pair for securing the nut.

If you're using a lock washer in any variety (including star type, split-ring type, or wavy type) to keep the nut or bolt from coming use, the washer is used on the side that's most likely to turn and drive into the surface - which in most case is the nut. The only time when you will use the washer on the bolt side is when the bolt screws ...

How To Use Lock Washers Diagram. Lock washers are installed by putting a bolt or screw through the center of the washer so that the washer is beneath the bolt or screw head or between the nut and the surface being fastened. Nuts are threaded onto the bolt to tighten the connection and.

Nord Lock Nlss Nlspss Wedge Lock Washers Securing And Anti Loosening Washers Securing And Anti Loosening Elements Fastening Technology Products Bossard Italy

For the BMW 5 E60, E61 2003, 2004, 2005, 2006, 2007, 2008, 2009, 2010 model year. Locate fuse box. In glove compartment. 1. Release both quick-release fasteners.

For the same reason, lock washers always go on the nut side to stop the nut moving. Lock washers are almost always used with a flat washer as well. The nut is also often smaller in profile than the bolt head. Not always, but often. The washer helps distribute the pressure that the nut places on the surface of the fastened objects.

China Din2520 9250 Different Types Lock Washers Double Sided Tooth Belleville Spring Self Lock Washer China Nord Lock Washer Sus316l Nord Lock Washer

Lawnmower manufacturers use screw-on nuts, lock washers and retaining pins to secure mower wheels. Occasionally, it becomes necessary to remove a wheel, perhaps to change it or in the case of a ...

In this animated video, we explain the principle behind the Nord-Lock washers. Our original wedge-locking technology secures bolted joints, even when exposed...

Step 1. Place the lock washer between the nut and the work surface if using a nut-and-bolt configuration, or between the fastener head and the work surface if using a tapped hole configuration. In other words, the bolt goes straight into the hole and doesn't poke out the other end, so no nut is used.

If a lock washer is required, it will be placed on the bolt followed by a second standard washer. Step 3 Align the holes for the joint you are connecting and push the shaft of the bolt through them. The washers should be pressed between the head of the bolt and the material of the joint.

1 Apr 2020 · 3 answersThey gave you four lock washers instead of 4 locking nuts. No problem. Install the bolts as shown in the instructions. Then install a flat ...Should a washer go on nut side, or the bolt side ...8 answers12 Nov 2015How to put the washers on the screw - Home ...5 answers10 Mar 2016More results from diy.stackexchange.com

Differences Between An Internal Tooth Lock Washer & An External Tooth Lock Washer. Tooth lock washers are made with small, sharp teeth formed around the inner hole or outer diameter (O.D.), depending on the type. An internal tooth lock washer has teeth around the center hole, while the external tooth lock washer boasts of teeth around the O.D. Both of these fasteners provide a locking ...

Buy M8 304 Stainless Steel Flat Washer And Split Spring Lock Washer Assortment Set 100sets Pack M8 Online In Usa B08htxpl7w

Loose bolts can lead to all kinds of problems in any application. Vibrations are one of the most well-known causes of loose fasteners. So fasteners were made...

18.04.2020 · Tip: The lid lock mechanisms on some washers are heat-activated, which means overriding them is as simple as letting them cool off. Let the washer sit unplugged for about 10 minutes, then try lifting the lid. If it opens, you're all set. If it still won’t budge, proceed to Plan B. 2. Shut off the water by turning the twin supply valves counterclockwise. These valves will either be located in ...

Fuse box diagram (location and assignment of electrical fuses) for Dodge Charger (2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018, 2019).

Some of the lid lock mechanisms on washers are activated by heat, meaning bypassing them can be as easy as letting them cool down. Allow your Whirlpool washing machine to sit unplugged for at least 10 minutes. Then, attempt to lift the lid. If it will raise, then you’re all set! If the lid lock is still engaged, proceed with the steps outlined below. Step One: Turn off the Water. With your ...

(30A) Headlamp washers. F4 (15A)Sea theater. F5 (30A) Seat adjustment. F6 (20A) Heated rear window. F7 (5A) Door lock heater, central locking, alarm system, convertible roof. F8 (15A) Horn. F9 (20A) Audio system . F10 (30A)ABS/traction control, suspension adjustment. F11 (7,5A) Headlamp -left. F12 (7,5A) Headlamp -right. F13 (5A) Electric windows- rear (2door) F14 (30A) Electric windows. F15 ...

Nord Lock Nlx Wedge Lock Washers Securing And Anti Loosening Washers Securing And Anti Loosening Elements Fastening Technology Products Bossard China

Lock Washers: Lock washers are designed to secure fasteners that have a tendency to rotate or lose friction. Although though there are several different types of lock washers and is each designed for use with a particular fastener or application, they all work under the same principle. The washer is designed to exert a load, partially deform, and lock a fastener in place.

Buy Cicidorai 100pcs 1 4 20 X 1 2 3 1 1 2 2 1 2 304stainless Steel Hex Head Screws Bolts Flat Washers Nuts And Lock Washers Assortment Kit Full Machine Thread With Storage Box Online In Indonesia B08zcn2tg2

0 Response to "42 how to use lock washers diagram"

Post a Comment