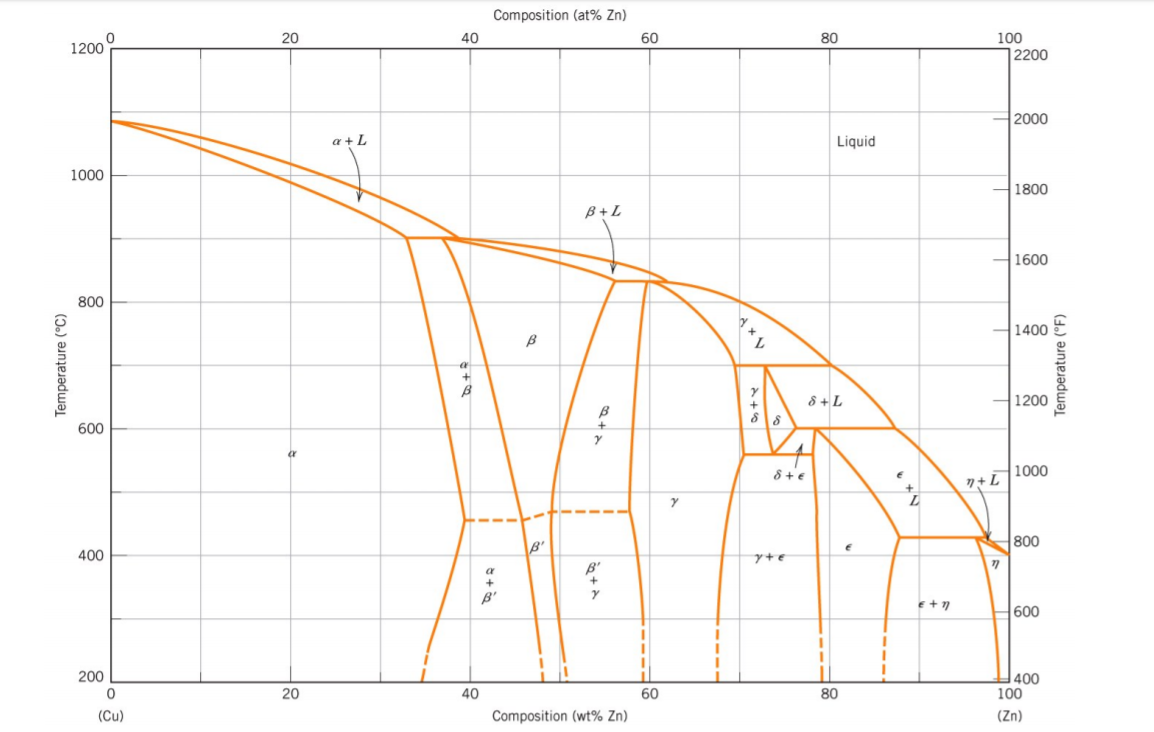

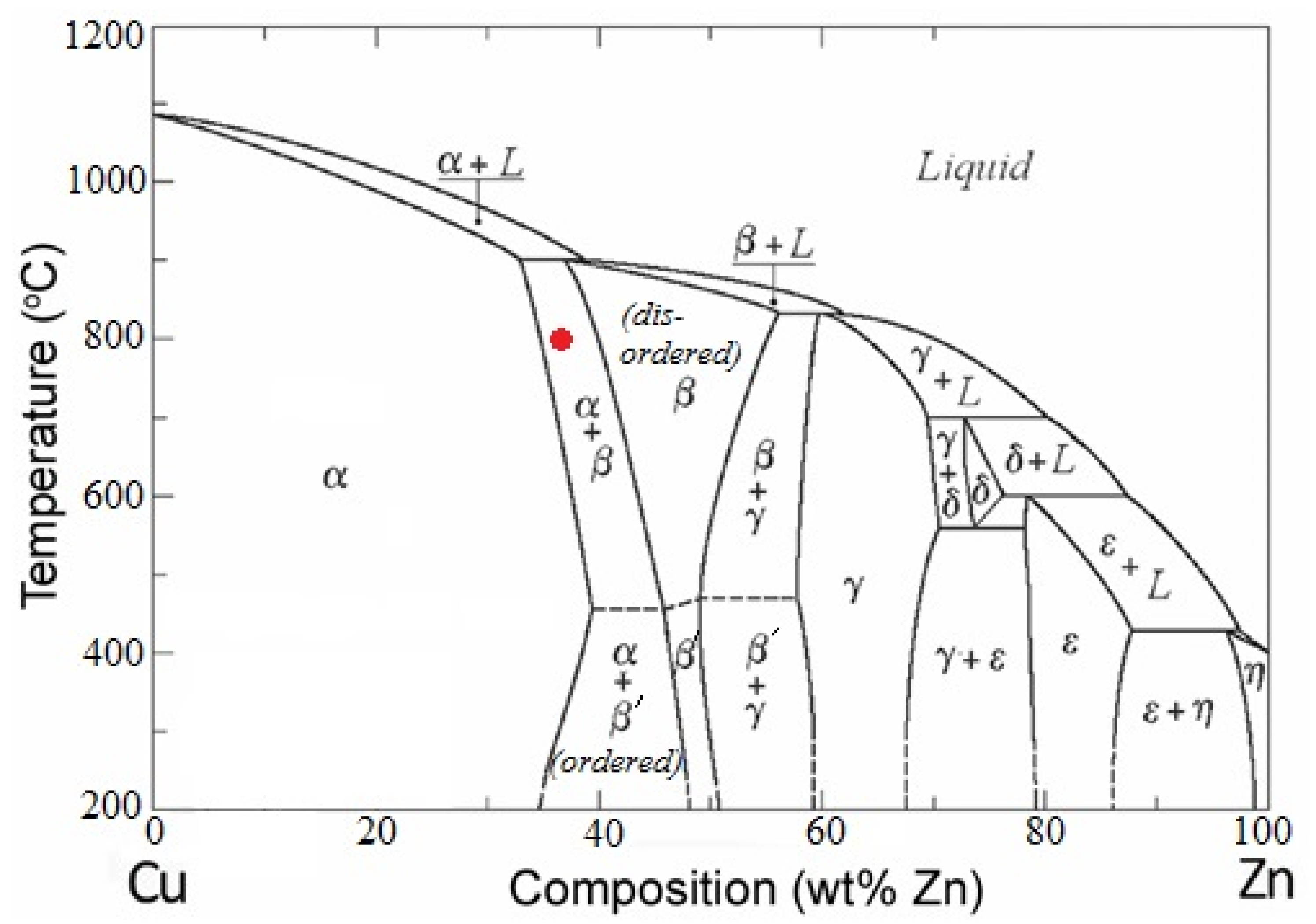

41 zn cu phase diagram

Electrochemistry: Galvanic Cells and the Nernst Equation Zn (s) --> Zn 2+(aq) + 2 e -. Oxidation. Cu 2+(aq) + 2 e - --> Cu (s) Reduction. The electrochemical cell forces the electrons to flow through a wire as they go from Zn to the Cu 2+ ions. The electrochemical cell consists of two "half-cells" that correspond to each of the above half-cell reactions. For the half-cell corresponding to the ... Zn-Mg and Zn-Cu alloys for stenting applications: From ... The chemical compositions of the zinc alloys as determined by inductively coupled plasma optical emission spectroscopy (ICP-OES) are presented in Table 1. Table 1 Chemical composition (wt.%) of Zn-Mg and Zn-Cu alloys determined by ICP-OES. Open in a separate window

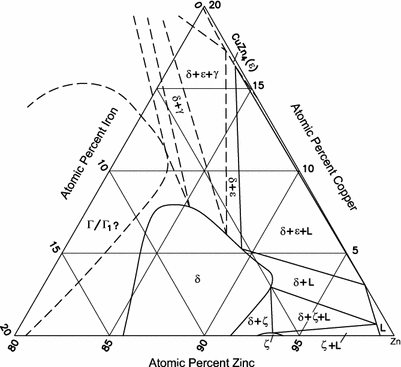

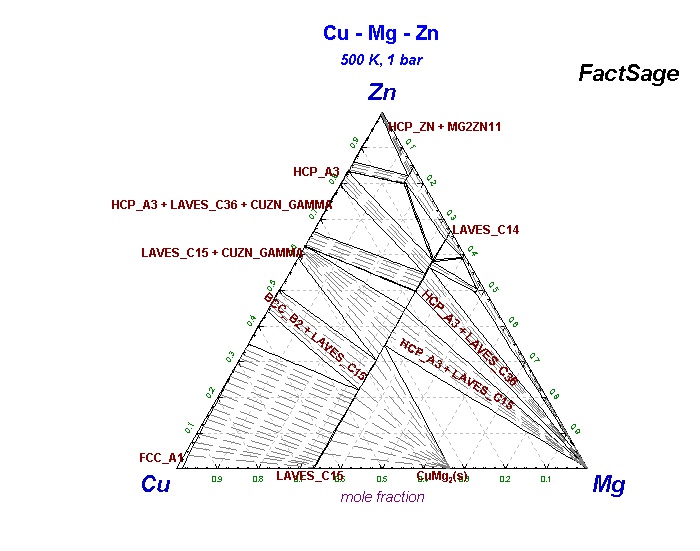

Ternary Alloy Phase Diagrams - Phase Diagrams - Beyond ... For the sake of clarity, grid lines are not superimposed on the phase diagrams. However, tick marks are provided along the composition scales as well as the temperature scale.which is shown in degrees Celsius. Celsius temperatures can be easily converted to degrees Fahrenheit using the table in the Appendix.

Zn cu phase diagram

Learn about Galvanic Cell. Equation, Construction - Embibe Ans: The chemical reaction responsible for the generation of electric current from chemical energy in a galvanic cell is a redox reaction. A galvanic cell is composed of two half cells, i.e., oxidation half cell and reduction half cell. The oxidation occurs at the oxidation electrode, i.e., an anode and it involves the liberation of electrons. Microstructure and yield phenomenon of an extruded Mg-Y-Cu ... Schematic diagram of the interaction of dislocations with solute atoms and particles. 3.2. Mechanical properties Fig. 10 shows the engineering stress-strain curve of the extruded alloy at room temperature and different strain rates. Microstructure and Mechanical Properties of Zinc Matrix ... Niu et al. (2016), added 1.0 wt% Mg to Zn/3.0 Cu alloy, and the yield strength and ultimate tensile strength increased from 214 and 250 MPa to 427 and 440 MPa, respectively, while the elongation dropped sharply from 47 to 1%. Although the alloying method enhances the strength of zinc, the plasticity will be greatly reduced, which seriously ...

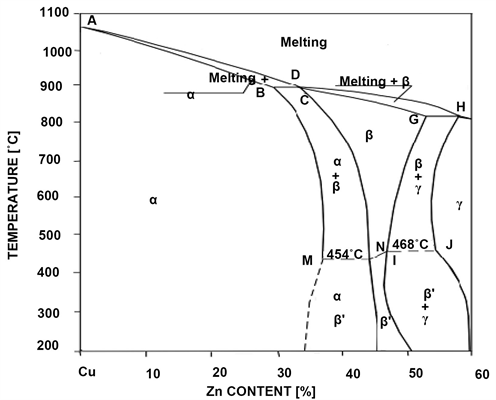

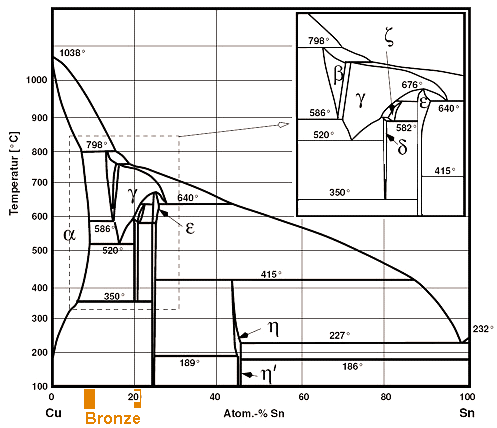

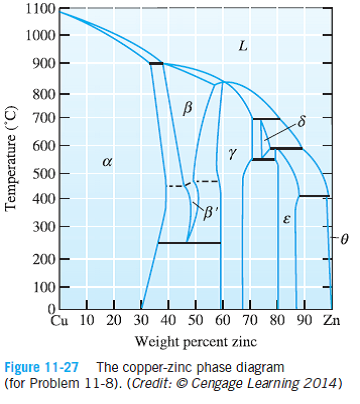

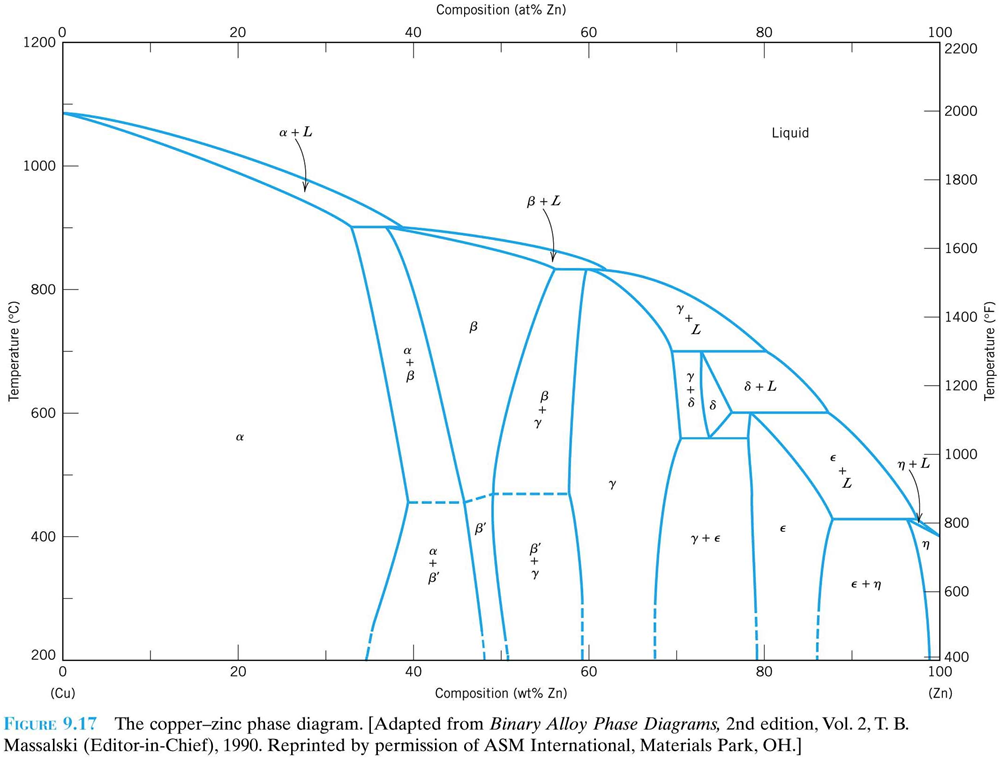

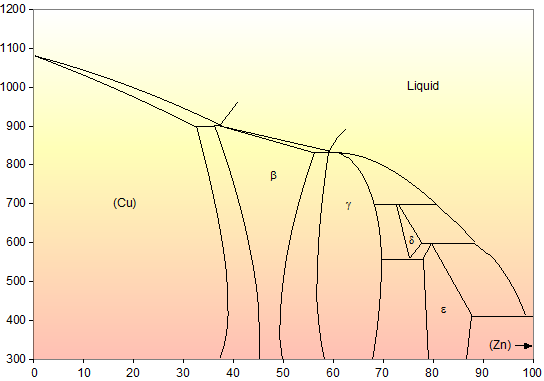

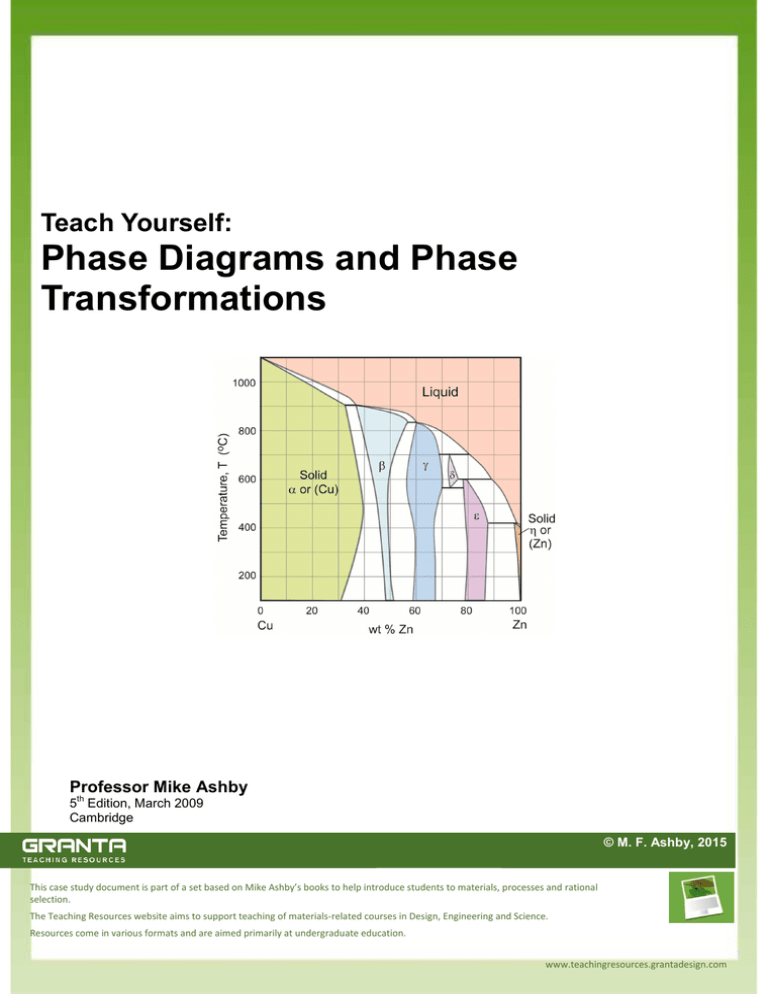

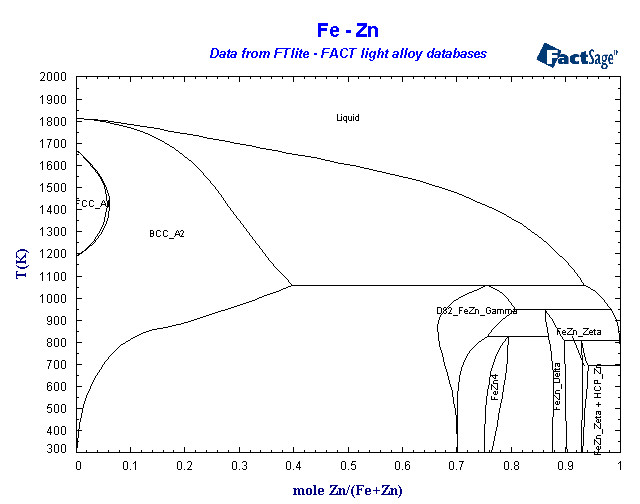

Zn cu phase diagram. Atomic control of active-site ensembles in ordered alloys ... The (Pd, M, Zn) γ-brass phase enables the controlled synthesis of Pd-M-Pd catalytic sites (M = Zn, Pd, Cu, Ag and Au) isolated in an inert Zn matrix. These multi-atom heteronuclear active sites are... Meng 482 T3-20-21-1.pdf - Meng 482 T-1 Phase Diagram Q1 At ... (a) That portion of the Cu - Zn phase diagram (Figure 11.18) that pertains to this problem is shown below; the point labeled A represents the 90 wt% Zn - 10 wt% Cu composition at 400 C (673 K). As may be noted, point A lies within the e and phase field. Phase Diagrams - Materials Science & Engineeirng ... Database of over 28,500 relevant, critically-evaluated phase diagrams with commentaries for inorganic compounds (ceramics and glasses). You can view the diagrams and associated commentaries, and download a Phase Equilibria Diagram viewer to digitize and manipulate the diagrams. Electrodeposition of Zn-rich CuxZn(1-x) Films with ... structure according to the Cu-Zn binary phase diagram,5 with a Cu content of at most 65 atomic percentage (at%). Other types of brass alloys include the β-brass, which contain about 45-50 at% of Zn with a body-centered cubic crystal structure.6 Because of the higher Zn content, β-brasses are harder and suitable for casting.4 As the

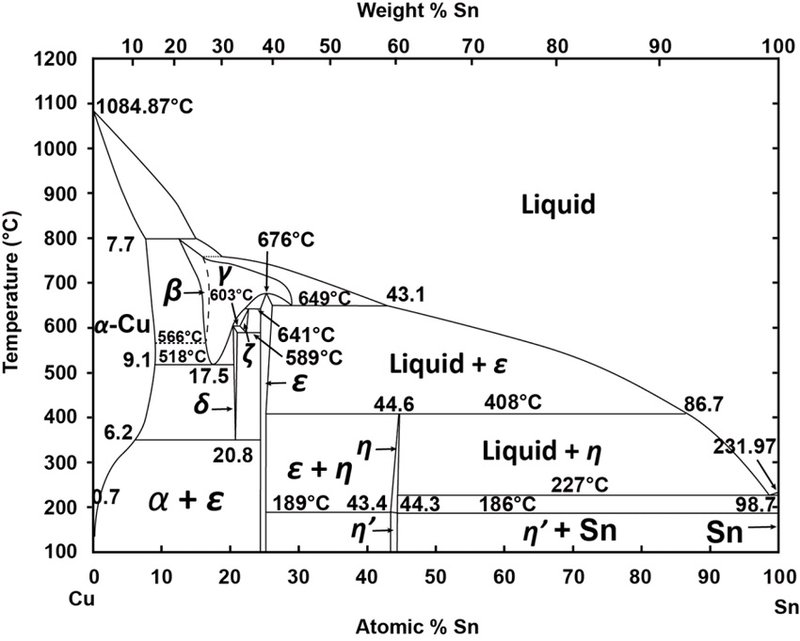

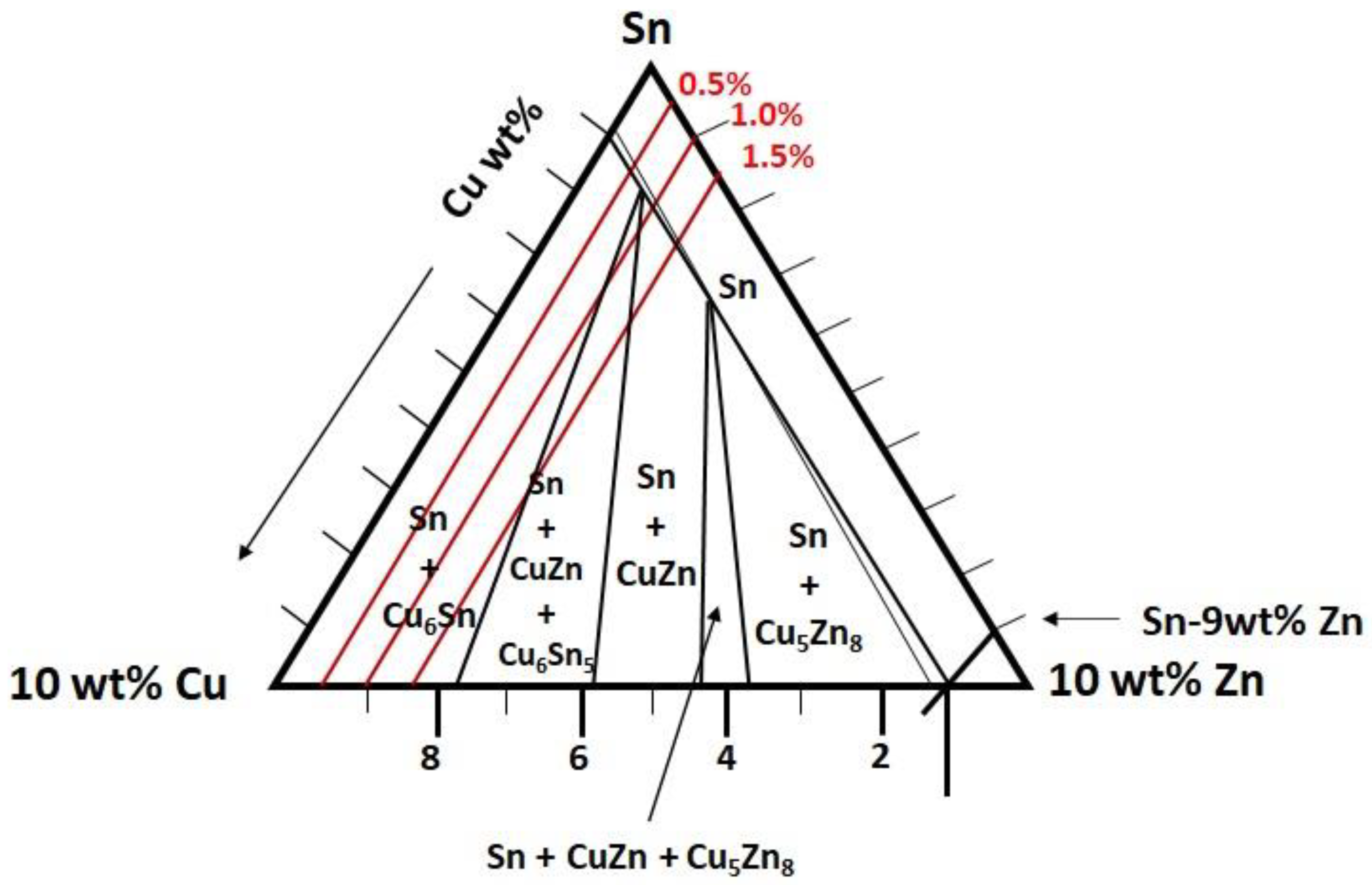

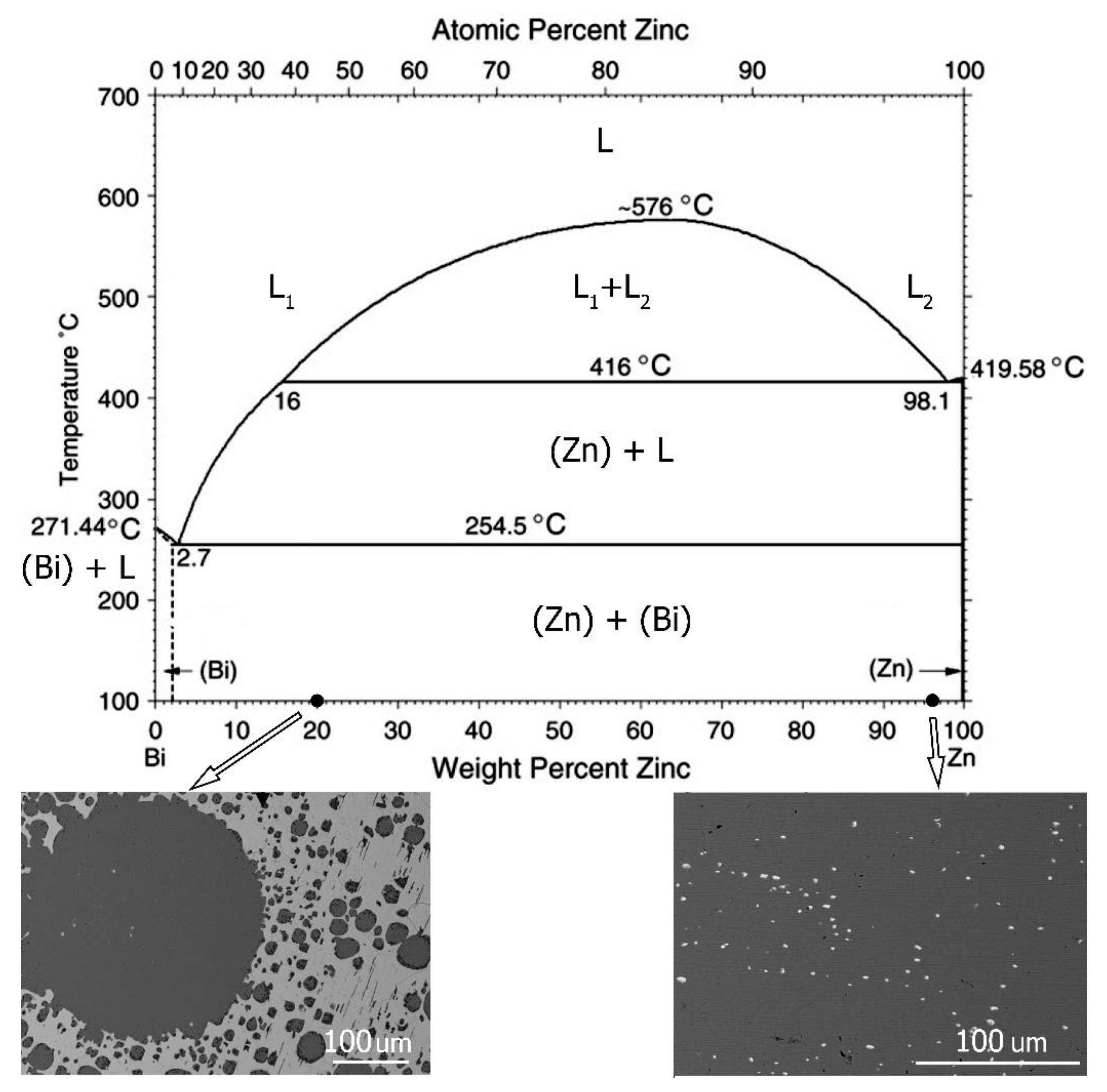

Forecast of Phase Diagram for the Synthesis of a Complex ... phase diagram of the AN−NBA system as well as for the synthesisofthecomplex,theenvironmentfriendlysolvent-free/ solid-state synthesis route has been adopted. The structural changes of the complex have been studied using Fourier ... (Cd 2+,Co,Hg,Mg 2+,F−,Ca,Cu,Zn2+,Cl ... Cu-Sn-Zn (Copper-Tin-Zinc) - SpringerMaterials Cu-Sn-Zn (Copper-Tin-Zinc) Book Title Non-Ferrous Metal Systems. Part 3 In Non-Ferrous Metal Ternary Systems. Selected Soldering and Brazing Systems: Phase Diagrams, Crystallographic and Thermodynamic Data Book DOI 10.1007/978-3-540-47004-5 Chapter DOI Microstructural evolution, damping and tensile mechanical ... It is apparent from the phase diagram of Zn-Al binary alloy that near the rolling temperature (400 ° o C), the solubility of Zn in Al (up to 70%) is much higher than that of Al in Zn (lower than 1%). Therefore, it is reasonable that Zn will diffuse into Al. Single-phase CZTSe via isothermal recrystallization in a ... The main intermediate phase during the synthesis of Cu 2 SnSe 3 was found to dissolve Zn up to 11.5 at% and, without Raman spectroscopy data, this phase could be easily confused with CZTSe because they are not optically distinguishable. On the other hand, the deviation of the Zn content in CZTSe does not exceed ±0.5 at%.

Induced activation of the commercial Cu/ZnO/Al2O3 catalyst ... High-angle annular dark-field STEM images and the corresponding EDS elemental maps of the fresh catalyst (CuZnAl-U), synthesized using a coprecipitation method, show a mixture of Cu oxides and Zn... CHAPTER 3.0 ELECTROCHEMISTRY_NOTES & TUTORIAL Q's - Flip ... A zinc bar is immersed in a Zn(NO3)2 solution, and a copper bar is immersed in a Cu(NO3)2 solution. The cell operates on the principle that the oxidation of Zn to Zn2+ and the reduction Cu2+ to Cu can be made to take places simultaneously in separate locations with the transfer of electron between them occurring through and external wire. Experimental Phase Diagram of the Ag-Se-Sn System at 250 ... The isothermal section of the experimental phase diagram Ag-Se-Sn at 250 °C is shown in Fig. 1. Due to the low melting point of pure tin (231.9 °C) and selenium (220.8 °C), two liquid phases, labeled as Liquid (Se) and Liquid (Sn) were observed in this section. cu-zn phase diagram - Diagram For You According to the Cu-Zn phase diagram, all historical tongues and shallots were made of α - brass, which contains only one copper - rich phase, namely, the fcc α solid solution of Zn in Cu (Figure 6). Since the Zn concentration does not ex- ceed the solubility limit in Cu, the next phase in the... 17.11.2014 ...

PDF Chapter 9 Phase Diagrams Problem Solutions 9.19 (the Cu-Zn phase diagram), which is shown below with a vertical line constructed at the specified composition: At 1000 C, a liquid phase is present; WL = 1. HW9 Solutions - Homework 9 - MSE 245 - BSU - StuDocu CHAPTER 9 PHASE DIAGRAMS PROBLEM SOLUTIONS. Excerpts from this work may be

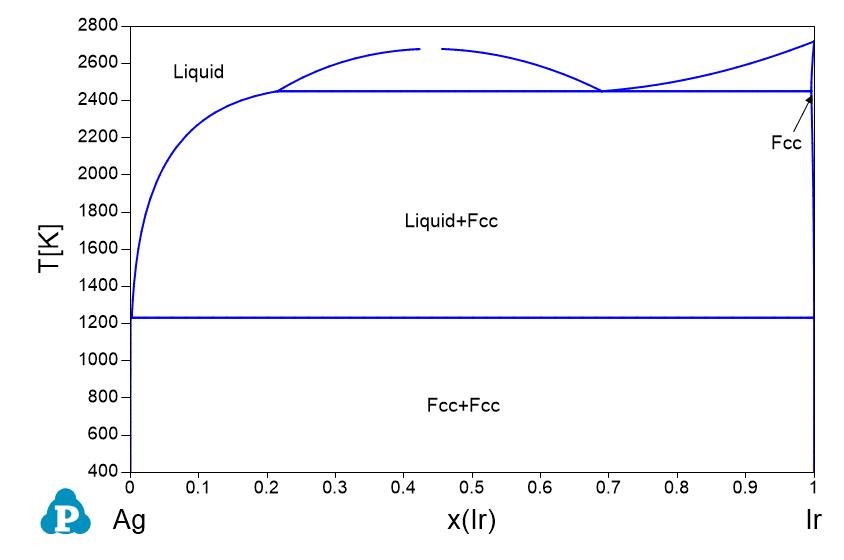

A machine learning-based classification approach for phase ... As a proof-of-concept, the focus is placed on predicting the number of coexisting phases across an isothermal section of each of the ternaries of the Al-Cu-Mg-Si-Zn system from the other phase diagrams.

Phase Diagrams - Properties of Chemicals and Materials ... Phase Diagrams of Ternary Iron Alloys REF TN693.I7 R34 1987; Phase Diagrams : A Literature Source Book REF QD503 .W575 ; Phase Diagrams for Ceramists REF QD501 .L592 ; Phase Diagrams of Copper-Oxygen-Metal Systems REF TN693.C9 C483 1989 ; Ternary Alloys : A Comprehensive Compendium of Evaluated Constitutional Data and Phase Diagrams REF TN693 ...

Zinc - Specific Heat, Latent Heat of Fusion, Latent Heat ... In the case of solid to liquid phase change, the change in enthalpy required to change its state is known as the enthalpy of fusion (symbol ∆H fus; unit: J), also known as the (latent) heat of fusion. Latent heat is the amount of heat added to or removed from a substance to produce a phase change.

What easily accessible material has melting point between ... Copper has a high melting point, Tin just 232C and Zinc 420C. Copper+Tin = Bronze, Copper+Zinc = Brass. The commercially available forms have higher melting points than you want.

37 tie line phase diagram - Wiring Diagrams Manual represented in the portion of the Cu-Zn phase diagram shown below (at point A). Furthermore, the compositions of the phases, as determined from the tie line are Cε = 87 wt% Zn-13 wt% Cu Cη = 97 wt% Zn-3 wt% Cu Inasmuch as the composition of the alloy C0 = 90 wt% Zn, application of the appropriate lever rule expressions (for

Microstructure and Mechanical Properties of WC-Co/WC-Co ... Considering the Cu-Zn-Ni phase diagram (Ref 29, 30) and the chemical composition in Table 2, these phases were considered to be copper solid solution (α-Cu (s.s)). The number of these island-like α-Cu (s.s) phases increased with increasing Co content in the base materials and can be clearly observed in the WC-Co brazed joints at 8 µm thickness.

Frontiers | Controlled Lithium Deposition | Energy Research FIGURE 4. Schematic illustration of the phase transition process on the Ag@Cu (A) and Au@Cu (B) substrates. The Li-Ag (C) and Li-Au (D) binary phase diagrams. SEM images of the cross section and the corresponding SEM-EDS mapping of Ag, Mg, Au, and Zn on Cu after lithium plating of 2.0 mA h cm −2 (E).

CuInSe2 and related I-III-VI2 chalcopyrite compounds for ... the basis of a phase diagram. The (I 2VI)-n(III 2VI 3) com-pound with n = 1isI-III-VI 2 (Cu 2Se+In 2Se 3 = 2CuInSe 2), the compound with n = 3isI-III 3-VI 5 (Cu 2Se+3In 2Se 3 = 2CuIn 3Se 5), and the compound with n = 5isI-III 5-VI 8 (Cu 2Se+5In 2Se 3 = 2CuIn 5Se 8). We use the phase diagram as the basis for designing the ...

Al-Cu-Zn Phase System Bibliography Report - SpringerMaterials Al-Cu-Zn Ternary Phase Diagram Evaluation (© 2004) Al-Cu-Zn Ternary Phase Diagram Evaluation (© 1992) References (421) Impact of COVID-19 pandemic; If you are having trouble in accessing SpringerMaterials remotely during the COVID-19 pandemic, Get help with remote access;

Based on the copper-zinc (Cu-Zn) phase diagram (Cu-Zn ... The Copper - Zinc Phase Diagram (37 points) Composition tots Zn) 1200 100 72200 2000 Loud 1000 1600 Temperature (°C) Temperature (F) 1000 800 400 400 100 60 Cu Composition (wt% Zn) The Cu - Zn phase diagram (from Binary Aloy Phase Diagrams, TB...

Microstructure and Mechanical Properties of Zinc Matrix ... Niu et al. (2016), added 1.0 wt% Mg to Zn/3.0 Cu alloy, and the yield strength and ultimate tensile strength increased from 214 and 250 MPa to 427 and 440 MPa, respectively, while the elongation dropped sharply from 47 to 1%. Although the alloying method enhances the strength of zinc, the plasticity will be greatly reduced, which seriously ...

Microstructure and yield phenomenon of an extruded Mg-Y-Cu ... Schematic diagram of the interaction of dislocations with solute atoms and particles. 3.2. Mechanical properties Fig. 10 shows the engineering stress-strain curve of the extruded alloy at room temperature and different strain rates.

Learn about Galvanic Cell. Equation, Construction - Embibe Ans: The chemical reaction responsible for the generation of electric current from chemical energy in a galvanic cell is a redox reaction. A galvanic cell is composed of two half cells, i.e., oxidation half cell and reduction half cell. The oxidation occurs at the oxidation electrode, i.e., an anode and it involves the liberation of electrons.

![Equilibrium Cu-Zn phase diagram [5] | Download Scientific Diagram](https://www.researchgate.net/profile/Pavel-Kejzlar/publication/316598481/figure/fig2/AS:616354306588689@1523961726879/Equilibrium-Cu-Zn-phase-diagram-5.png)

![2. The equilibrium Cu-Zn phase diagram. [61] | Download ...](https://www.researchgate.net/profile/Zhou-Peng-7/publication/322748528/figure/fig4/AS:587563039461383@1517097353986/The-equilibrium-Cu-Zn-phase-diagram-61.png)

0 Response to "41 zn cu phase diagram"

Post a Comment